To design efficient loading docks, determine the:

- Types and numbers of trucks that will use the docks

- Dimensions of the loading docks and doors

- Characteristics of the facility processes

Then, consider the dock height, loading bay width, and dimensions and layout of the building interior.

TRUCK SPECIFICATIONS

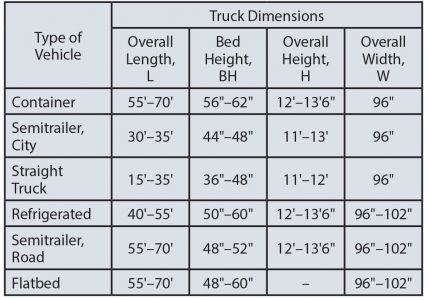

Determine the types and dimensions of the trucks that will use the docks. List each truck’s length, width, height and bed height.

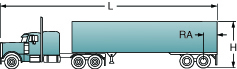

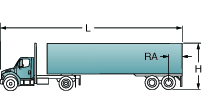

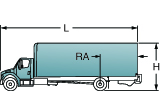

See Figure 21 through Figure 26 for the dimensions of common truck and trailer designs. Note that weight of freight can cause a variance of up to 6 in. in trailer and bed heights. The dimensions may also be affected by air suspension systems. Use Figure 21 through Figure 26 for preliminary design, but obtain actual truck dimensions before making final design decisions.

Figure 21: Container Truck

Figure 22: Semitrailer

Figure 23: Straight Truck

Figure 24: Refrigerated Truck

Figure 25: Semitrailer, Road

Figure 26: Flatbed Truck

Table 4

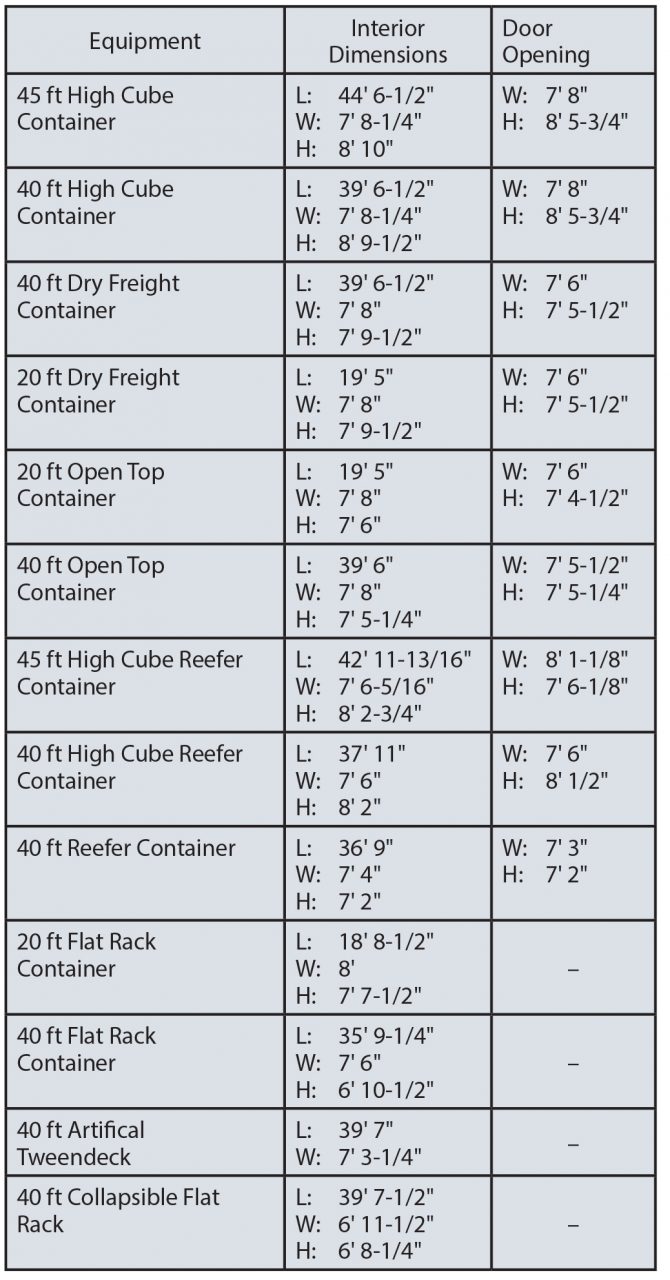

SEA CONTAINERS

Sea containers and refrigerated containers can have trailers with heights of up to 62 in. Facilities that must service sea containers may also frequently service low-bed trucks. The height difference can be from 30 to 62 in. Consider designing docks of various heights or installing equipment such as hydraulic truck levelers or elevating docks. Typical container sizes are listed in Table 5.

Table 5

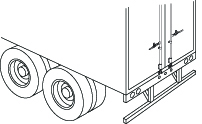

UNDERRIDE PROTECTION BARS

The underride protection bar, called the Rear Impact Guard (RIG) bar, is mounted at the rear of the trailer (Figure 27). Restraint devices attach to the RIG bar to prevent the truck from being driven away before loading or unloading is complete.

Figure 27

SET THE DOCK HEIGHT

The most important characteristic of the loading dock design is the height of the dock. The dock height must match the height of the docking trucks. The height difference between the dock and the trailer bed should be as small as possible. The dock leveler bridges some height difference, but the incline should not be too steep. A steep incline can cause insufficient forklift underclearance, and it increases maintenance demands on the equipment.

To determine the dock height, find the midpoint of the bed heights of the expected trucks. Most trucks require a dock height of between 46 and 52 in.

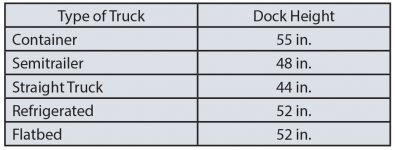

See Table 6 for dock heights that create level docks for common types of trucks.

Table 6

NOTE: Truck beds will rise and lower during loading and unloading.

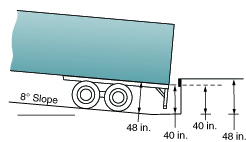

If the driveway is recessed, the dock height should be lower (Figure 28). A recessed parking area may lower the truck bed height by 6 to 10 in.

Figure 28

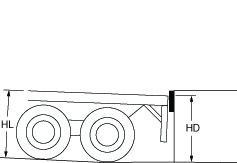

This is particularly important when a driveway approach declines to a level surface in front of the dock, and when the truck or trailer has its wheels positioned well forward of the rear of the vehicle.

For example, in Figure 29, the drive approach is an 8% decline leading to a level concrete pad at the dock. A typical trailer bed, which is at a 48 in. height (HL) from the decline drive, will be at approximately 40 in. (HD) at the dock. Therefore, if the dock is intended to service trailers with 48 in. bed height, the dock height should be at 40 in.

HL = Bed height when level

HD = Bed height at dock

Figure 29

Design the dock height based on the specific parameters of driveway slope, geometry of the recessed parking area, and bed heights of the expected trucks unique to your building.

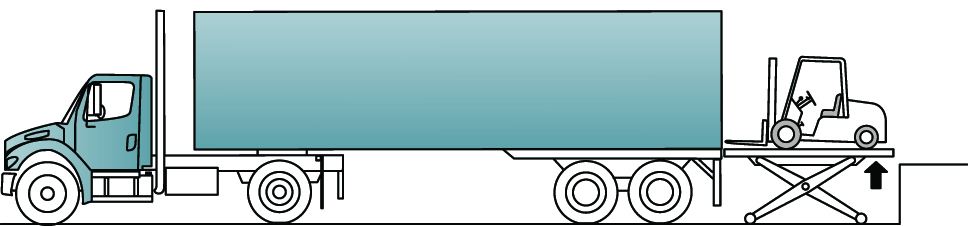

If the expected trucks have very high or low bed heights, provide dedicated dock positions with special driveways and equipment, such as an elevating dock (Figure 30).

Figure 30

For open docks, where the trailer doors are commonly opened after the trailer is parked, design a dock height low enough for the door clamp hooks to clear the dock as they are opened (Figure 31). 51 in. is a common dock height for this situation. If the driveway is recessed, lower the dock height further since the doors swing down slightly as they are opened. Lower the dock by about 1 in. for each 1% of recessed driveway grade.

Figure 31

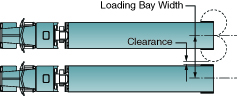

SET THE LOADING BAY WIDTHS

Each truck bay should be at least 12 ft wide to provide enough space for the trailers, which are 8’0″ to 8’6″ wide, to back squarely to the dock. To reduce congestion, design 14 ft wide bays. If swinging trailer doors will be opening or closing at the dock, the center distance should be at least 14 ft (Figure 32).

Figure 32

SELECT DOCK DOORS

A dock door is required for inside/outside loading docks. The most commonly installed doors are manually operated and are either an overhead sectional door or a roller door. A sectional door is smoother and quieter than a roller door because of rollers that run inside of tracks. Other advantages of a sectional door are:

- They are thicker and stronger than a roller door

- They can be insulated

NOTE: Install door track protectors to protect the door tracks.

Common dock door dimensions are 8’0″ in width with 8 ft, 9 ft or 10 ft heights. Consider extending the door 13 ft to 14 ft above the driveway and a minimum of 8’6″ wide if full access to the truck’s interior is required. Dock doors dimensions are determined by:

- Type of trucks being serviced

- Sealing system

- Environmental concerns

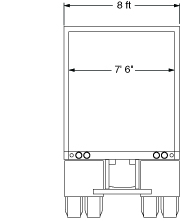

DETERMINE DOOR SIZES

NOTE: The maximum trailer size limits are 8’6″ wide x 13’6″ high (varies by state). With a special permit, a flatbed may exceed the maximum width.

Widths

Determine the door sizes along with selecting the sealing system. Keep doors as small as possible – usually narrower than 8 ft – in temperature-controlled docks, where energy is lost through doors. Space the doors 12 ft apart to accommodate most trucks, sealing systems, and communication light systems.

Dock doors narrower than 8’0″ are commonly installed with compressed foam dock seals for temperature control of refrigerated operations.

9 ft wide doors should be used to service 8’6″ wide trailers. Side-by-side palletizing is simplified, potential for product damage is reduced, and oversized loads can be serviced.

The doors should be between 8’6″ and 8’0″ wide to allow for trucks to park off-center. A 10 ft wide door can be designed for oversized loads. Note that wider doors require more building space, which may not be available.

NOTE: Compression of seals may reduce the effective width and full access to trailer.

Figure 33

Figure 34

Heights:

Doors are typically 8 ft, 9 ft, or 10 ft high. 8 ft high doors can accommodate many loading and unloading operations where height is not critical, but cannot accommodate floor-to-ceiling loading (Figure 35). 8 ft high doors do not maximize the usage of the available height in the trailer, which leads to higher freight costs.

Figure 35

A 9 ft high door allows for improved floor-to-ceiling loading (Figure 36) as a higher load can pass through the door. Fuller, tighter loading makes for better space utilization with a decreased risk of product damage due to door impact. The 9 ft height suits a wide range of applications. However, in trailers with lower height there may be a gap between the trailer and the top of the door. The gap can be closed off with a dock seal or shelter.

Figure 36

A 10 ft high door services the full range of loading and unloading operations (Figure 37). 10 ft high doors accommodate trailers of heights up to and including high cube trailers and high cube sea containers.

Figure 37

To provide full access to the entire width and height of a full-size trailer, the dock door should extend the full height of the trailer (13 to 14 ft) above the parking area.

DESIGN THE DOCK INTERIOR

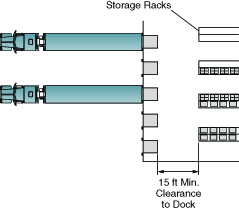

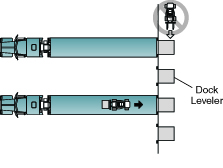

Design a forklift traffic aisle, 15 ft wide minimum, behind the loading ramps. This aisle provides better visibility, allows forklifts to maneuver behind the trailers, and permits two-way traffic parallel to the dock face. Aisles that are 15 ft or wider allow forklift drivers to drive straight onto the docklevelers, which reduces injury hazards and equipment stress (Figure 38).

Figure 38

Put restrictions into place that deter forklift drivers from driving parallel to the dock face (Figure 39), which can result in collisions with forklifts backing out of trailers.

Figure 39